LabGuy's World: THE BIRTH OF

VIDEO RECORDING

By Charles P. Ginsburg CHARLES

P. GINSBURG FIRST DELIVERED THIS PAPER, IN SLIGHTLY DIFFERENT FORM, AT

THE 82nd CONVENTION OF THE SOCIETY OF MOTION PICTURE AND TELEVISION ENGINEERS

(S.M.P.T.E.) ON OCTOBER 5, 1957, 18 MONTHS AFTER AMPEX DEMONSTRATED THE

WORLD'S FIRST PRACTICAL TELEVISION VIDEO TAPE RECORDER. Transcribed by

Jerry Burling, SBE Chapter 47

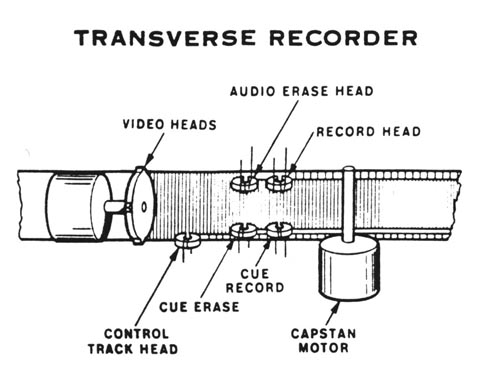

The work, that led to the development of the first practical television video tape recorder, did not flow from divine inspiration or a miraculous break through onto the road to success. The first video recorder was the end product of over four years of hard and, at times, inspired, work by a team of individuals, who brought their own unique skills to bear on the endless problems that confronted this pioneering development team. At times, progress was agonizing slow, and twice, during this time period, the project was placed on the shelf, to await an uncertain destiny. As it turned out, however, much of the real work started after we made our first, real successful demonstration. But this triumphant display was but in the dim, distant future, when the project commenced back in 1951. In October, of that year, after several lengthy disputes on the question of how television recording might be accomplished on magnetic tape, Alexander M. Poniatoff, founder and, at that time, President of the Ampex Corporation, and Myron Stolaroff and Walter Selsted, Poniatoff's two top technical aides, agreed that a relatively small sum of money should be appropriated for the purpose of investigating a rotating head method to video recording. The rotating head method was one of a number which had been proposed, and discussed by Stolaroff and Marvin Camras of the Armour Research Foundation, of which the Ampex Corporation was a licensee. The other methods, under discussion, were high speed tape movement and time division multiplexing techniques. These dialogues finally rejected all but the rotating head approach. Accordingly, as a direct result of a scientific conclusion from the consultation interplay, a start up project was authorized in December of 1951. The opportunity to join Ampex, on the project, was one that I jumped to accept. Prior to the actual start date of the project, the entire conception of the system was merely this; three heads were to be mounted on the surface of a rotating drum that would be scanning, in arcuate fashion, the surface of a 2 inch wide magnetic tape. The head-to-tape relation speed was to be approximately the equivalent to 2500 inches per second (IPS) past a stationary head, to allow enough bandwidth for the recording of a dependable signal of at least 2 1/2 megacycles of frequency response. The actual tape speed was to be 30 IPS. In the early days, the project had a rather low priority and in May, of 1952, the entire video tape recorder program was suspended, for three months, in favor of a crash project to turn out a one-of-a-kind instrumentation recorder. This turned out to be a fortunate interruption, as it allowed me to come into contact with a 19 year old, part time engineering student by the name of Ray M. Dolby. Although, at that time, he had no formal engineering training, his technical understanding, and ingenuity, made him a key figure in the development activity, from his very first contact with it. Dolby, excited by the undertaking, dropped out of school when the endeavor was revived in August of 1952. Dolby was immediately rewarded by having his student draft deferment denied and was forthwith inducted into the U.S. Military, in March of 1953. In October, 1952, we demonstrated an almost unrecognizable picture. This achievement was promising enough to maintain the enthusiasm of Ampex management. We designed, and built, a second system, that was up and running in the early days of March, 1953. In this new machine, we utilized 4 heads mounted around the edges of the rotating drum, instead of the earlier three, in order to utilize a two-way switching system, in which the output, during playback, of either of the two sets of diametrically opposed heads, spaced at 90 degrees around the drum, could be selected by the RF switcher. The radius of the arc, as the heads scanned perpendicular to the tape travel, was about 1 1/4 inches, which permitted approximately 105 degrees of arc to be described by each head, as it swept across the 2-inch wide tape. In the early stages, an amplitude modulation system was used, which employed RF signal limiting, in a clamp modulator. The capstan motor was driven directly from the 60 cycle power line source and the high speed head drum motor was driven by a power amplifier, whose input was the fifth harmonic of the power line frequency. A photocell received the reflected impulses from a light source focused on a ring mounted on the rotating head assembly for tachometer speed control of the rotating drum. The 300 cycle photocell drive signal was also recorded on one edge of the tape, by means of a conventional, stationary head, forming a control track. During playback, this 300 cycle signal, derived from the control track head, was used as the input signal to drive, and control, the drum power amplifier. Although we were pleased by some aspects of the reproduced picture, the delight was attenuated, close to the vanishing point, by a number of unexpected problems that faced us. The pitfalls, of the discontinuous method of video recording, were becoming painfully obvious. The odious "venetian blind" effect came into being, which described a very unpleasant effect, where flaws, at the points representing the switching cross-over positions, from one head to the next during the RF switching process, were prominently displayed on the picture monitor. The unsuitability of this method of control, and the necessity for extreme accuracy in the positioning of the tape, relative to the rotating heads, was graphically apparent and a good many hours were devoted to analyzing complex errors in the rotating head sweep geometry. This investigation revealed that major revisions, in overall machine design, would be necessary before a successful rotating head VTR could be realized. By the mutual consent of all concerned, the project was shelved, in June of 1953, in favor of certain other high priority company programs then in existence at Ampex. But the understanding was that the entire subject, of video tape recording, would be reviewed, and revived, within a few months, including proposed solutions to several of the problems experienced by us up to that time. However, due to unexpected pressures from other engineering needs, project activation did not come about as, or when, agreed. Between June of 1953 and August of 1954, the Ampex Video Tape Recorder Agenda had no continuous status, but a certain amount of progress had been made on specific problems by means of some very minuscule man hour and money allotments, some authorized and some bootlegged. Encouraged by these problem solving advances, a report was drafted and submitted to Ampex management, together with an urgent request for approval of an 80 man hour time allotment to make modifications and to demonstrate the revamped machine, which then became known to us as the Mark I. After receiving verbal notification that the authorization would, indeed, be forthcoming, Charles E. Anderson and I changed the control system configuration and conducted a demonstration of the revised machine for an Ampex management committee. As a result, on September 1, 1954, the VTR program commenced in earnest. At the outset, there were two major technical changes to the system. The first was a departure from arcuate sweep configuration to the geometry that became the standard in the late 50's, in which the tape was wrapped around the drum, utilizing a vacuum guide, and the information, written on the two inch tape by the rotating head drum, was written perpendicularly across the tape, in straight lines. The second alteration was the development of an automatic gain control system (AGC) to compensate for all of the fluctuations caused by the instability of the rotating head. Late in September, Charles Anderson, who was later to become the father of the quad tape FM system, Shelby Henderson, our model maker, and I, were joined by Fred Pfost and in October by Alex Maxey. At the beginning of this entirely new project, we had, in our possession, a total of six individual video heads; four on the operational rotating drum, and two spares. These heads were the first combination of ferrite core and metal tips, made especially for recording video. They had been constructed a year and a half earlier and although there were quite crude, they worked at least well enough not to constitute any real limitation to system performance, during those difficult initial efforts. Therefore, in the fall of 1954, we were not worried about the manufacture of more heads, assuming that, once again, we could accumulate the necessary ingredients of ferrite, metal tips, epoxy, and elbow grease. Maxey was assigned to this task, which proved to be a severe aging experience for him. The problem was that the heads would not remain together due to the high centrifugal forces caused by the rotating head drum. The protective supports, holding the heads in place, had been much more secure in the old configuration and we did not now have time to wait for the green epoxy to cure. Alex reshaped the original composite heads and installed them on the new drum assembly. It was several months before we were able utilize a new, and improved, design. In December of 1954, we made our first picture employing the new drum geometry. The results were gratifying in terms of improved stability, although it took a great deal of faith and understanding to be optimistic in the face of some rather gross shortcomings in the reproduced picture. The AGC system was not yet ready and it was beginning to become apparent that there were very difficult problems in its design.  Meanwhile, Ray Dolby, who had finished his tour of military service, returned to Ampex on a part time basis, while continuing a full college program. He began work on a simplified FM modulation method. Anderson had used fairly conventional reactance tube techniques, heterodyning the sidebands, from the 50 megacycle region, down to frequencies more suitable for video tape recording and subsequently moving the playback information up to about 50 megacycles for transmission through high frequency IF amplifiers. Dolby, on the other hand, designed and built a multivibrator oscillator, which could be modulated by applying the composite video signal directly to the control grids of the oscillator tubes. Since the free running frequency of the multivibrator oscillator could be set to a value suitable for transmission by the rotating heads and the magnetic tape, circuit complexity, and perimeter timing errors, were greatly reduced. On February 25, the quality of the picture, obtained by utilizing Dolby's multivibrator modulator, were even better than those from the reactance tube system earlier in the month. On March 2, 1955, we gave a very convincing demonstration for the Ampex Board of Directors. The video resolution was extremely low, since the system frequency response was somewhat less than 1 1/2 megacycles wide. The picture monitor had to be operated with a short time constant in the horizontal AFC circuit, due to large velocity error variations in the head drum, which, at that time, was belt driven. The month that followed was one of careful deliberation about the many questions that remained, all, of which, must be answered, with reasonable accuracy, in order to steer the project in the proper direction. It seemed that we had come a long way, in a short time, by using the broadside attack method to the many problems facing the venture. This approach would certainly have to become more refined before we could be certain that we were on solid ground in our efforts to turn out a commercially acceptable product. Rather than give a full account of what we knew we didn't know, let alone what we didn't know we didn't know, let me only say that we proceeded under a new engineering project authorization, that contained a large measure of caution, but also comprised, as its major objective, the design of a system that would be suitable for public demonstration within one year. Phillip L. Gundy, then General Manager of the Ampex Audio Division, of which the entire video tape project was a part, made a major contribution by moving our entire development operation to more isolated quarters, with five times as much space as we had before. Now, truly behind closed doors, we feverishly went to work. Maxey conducted some after hours experimenting, during February of 1955, and discovered some very significant phenomena connected with certain video tape reproduction characteristics. He found that he could control, in a positive fashion, the amount of information read out during playback by each of the four heads, per unit of arc sweep, by varying the tape tension in any one of three ways; (1) at the reels, (2) by moving the vacuum female guide toward, or away from, the rotating head drum, or (3) by varying the vacuum pressure, which held the tape in the female guide. Although we were concerned with the extent of the non-linearities which might be introduced into the picture by using the guide position as an information rate control and did some experimenting with a correction method in which the amount of vacuum was varied, we subsequently discovered that the non-linearities, caused by the first method, were quite objectionable. The innovation, of varying the tape tension, proved to be one of the major break throughs in the entire development program. This was an excellent, and ideal, solution to the problem of rate changing, as the four rotating heads wore down and swept in a smaller radius, due to friction wear. Varying tape tension was also an answer to part of the question of ultimate interchangability of recorded tapes from one machine to another. Radical changes were made in the design of the individual magnetic heads, going to a sandwich type of construction that provided the necessary mechanical support and which was far more reproducible in terms of manufacture. Thankfully, during this time, we were able to devote a good deal of quantitative effort into the characteristics and performance of the video heads. The entirely new video head development program was carried by Pfost, who exhibited unbelievable tenacity and patience in coping with the all important microcosms of head construction. Anyone, who has attempted to wrest adequate frequency response from magnetic heads, at wavelengths below 200 micro inches, is well aware of the enormous problems that were faced by him. The frequency response, of the modulation system, was extended in bandwidth so that it would be suitable to operate with an FM carrier frequency of six megacycles, if such an operating frequency should subsequently be usable. The RF switcher, which previously had been a two mode device, was replaced with a unit with four channels, that would allow the conduction of only one head channel at a time. Considerable improvements were made in resolution and also in signal-to-noise ratio. The drum was stabilized sufficiently to allow the display of video tape pictures on a standard monitor. We made no attempt, during this period, to present a "dressed up" machine to anyone and had built, for scientific testing purposes, a rather crude looking wooden cabinet containing a metal top plate and a few electronic units, which operated in conjunction with two partially filled 19 inch standard equipment racks. At a very small demonstration, given to some officers of the firm toward the end of 1955, it was suggested that we should package our efforts more attractively, since this was going to be a very expensive machine. And so, accordingly, Anderson designed the Mark IV console, with its compact rack arrangement. It was also decided, at this time, that we should start thinking seriously in terms of a surprise demonstration at the National Association of Radio and Television Broadcasters (NARTB, later to be the NAB) Convention in Chicago, in April of 1956. In early February of 1956, we gave a demonstration for what was originally scheduled to be a very small Ampex management group, but turned out to be one attended by at least 30 Ampex people. For all of us, on the engineering development project, this was the most dramatic exhibition we were ever to make. The guests arrived, were seated, and a few words were spoken to the effect that the recorded television production, they would be seeing, we had produced ourselves. The Mark IV was started in playback mode and displayed a program we had recorded about an hour earlier. Next, we announced that we would record a sequence of everyone who was now in the room and would immediately play it back for everyone to see. We recorded for about two minutes, rewound the tape, and pressed the playback button. Following the playback of the two minute sequence, there was absolute silence. Then, the entire group rose to their feet and shook the rafters of the building with shouting and hand clapping. Two of our developmental group, who had continually been at odds with each other, shook hands and slapped each other on the back. Many of us had tears streaming down our faces. Quite a few visitors arrived to see our new invention during the next couple of weeks, including Bill Lodge of CBS, Frank Marx of ABC, and representatives of the CBC and the BBC. All visitors were sworn to absolute secrecy and were, generally, ushered in and out separately, so that they would not see each other. As a result of Lodge's visit, arrangements were made to use the Mark IV demonstration machine, which had not yet been completely assembled, for a surprise showing at the annual CBS Affiliate's Meeting, that was scheduled to occur one day before the opening of the NARTB Convention. With about six weeks to go before the convention, working hours were considerably extended in order to complete construction on the Mark IV and, at the same time, to continue developmental efforts to improve signal quality so that the picture, to be demonstrated at the convention in Chicago, would be as good as CBS was expecting it to be. Activity became furious. The administrative engineer, in charge of the now enlarged project group, shed his business suit in favor of a work shirt and jeans, and spent most of his regular working time, plus nights and weekends, modifying mounting brackets for the new Mark IV console, manufacturing cable assemblies, and building re-designed electronic units.

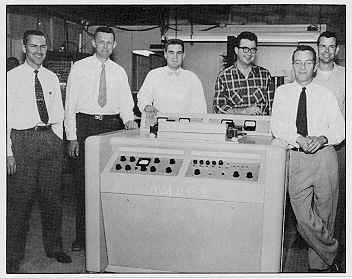

Ampex Mark IV Prototype VTR The three year old idea, of placing the video head switching transients in the middle of the horizontal blanking interval, was rushed into hardware form with the manufacture of a blanking switcher and was integrated into the system as a toggle switch option. Also incorporated was an automatic rotary head degaussing system, to eliminate the annoying task of having to demagnetize the video heads, after each recording operation, prior to playback. Meanwhile, it had been decided that the Mark III, the machine used for prior demonstrations in February, should be used for press showings, at the Ampex headquarters in Redwood City, California, on the same day that the NARTB Convention was to begin in Chicago. Therefore, while the Mark III machine was being utilized for development purposes, barely leaving enough time for the development of the Mark IV, it also had to be prepared for its initial press debut. The true orphan of the project, the audio, which had been sadly neglected up to this point, had to be upgraded to approach professional standards. There were many heroes during this period, but leading them all was Pfost. Fred experimented with the video heads up to the morning before embarking for Chicago. He varied tip structure, core structure, core windings, gap spacing, guide setting, current setting, and continuously built new heads. He accomplished an unbelievable amount of work during this interval. In the last four weeks prior to the Chicago showing, Pfost put in an average of well over 100 hours per week. The Mark IV was finally broken down into its component parts and shipped to Chicago. Three days before its press showing, the Mark III, Redwood City, machine, was in serious mechanical trouble. Those of us, headed for Chicago, left Redwood City, wishing the stay-at-homes good luck, trying not to think about their difficulties. The NARTB demonstrations were scheduled for Saturday. By Thursday afternoon, the Mark IV was assembled at its convention location in Chicago and was making the best pictures we had ever seen from video tape. Then, a predictable situation occurred. The CBS engineering staff announced that the Mark IV pictures were just not good enough. The signal-to-noise ratio was too low and the noise banding was unacceptable. Between Thursday and Friday evenings, we cured all of the complained of problems. By dint of cutting, trimming, adjusting, and by the fortunate last minute delivery of some new tape samples that greatly exceeded the performance of anything we had seen before, everyone was satisfied with the final output of the machine. When we checked with the crew in Redwood City, we found, to our relief, that they had solved all of their mechanical problems and were ready for the press exhibition. The Chicago NARTB demonstrations were like dropping a bomb shell on the broadcasting industry. Pandemonium broke loose and Ampex was literally flooded with orders. From the time of the CBS Affiliates meeting on Saturday morning, through the NARTB demonstrations which extended until the following Thursday afternoon, the Mark IV machine performed better than we had any right to expect. And in Redwood City, the performance, for the press, was sensational, exciting, and satisfying. However, the next several months were just hard work. Four months earlier, Ampex had expected to deliver five prototype machines, beginning in late summer or early fall, to various government agencies for evaluation, along with a gradual program leading to the delivery of machines for use in the television industry starting in 1957. Now, with the sensation caused by the NARTB showings, we were faced with the pressure of manufacturing 16 hand built machines, most of them going to broadcasters for their immediate on-the-air use and, at the same time, we had to gear up for the full scale production of machines for the entire broadcasting industry. In spite of the subjectively good pictures we had demonstrated in April of 1956, a survey of the tasks, that had to be covered before our first machine could be released for general on air use, revealed that we were still standing on shaky ground. Until then, neither man power, nor machine facilities, nor technical advances, were sufficient to properly evaluate magnetic tape for video recording purposes. And until we could rate tape samples from manufacturers, using more definitive terms than "fair output," "too many dropouts," or "doesn't wear well," there wasn't much that could be accomplished toward developing a really satisfactory recording tape. The tape evaluation program consumed many hundreds of hours and was the cause of severe headaches to the tape manufacturers, to us, and to our early network customers. With a, then, predicted head life of 100 hours, we could not continue to make heads in a tedious one-at-a-time fashion. The many parameters in head construction, several of which had to be varied widely, in a cut-and-try fashion, in order to squeeze out a precious few more db of signal-to-noise ratio for the April demonstrations, had to finally be decided upon, and fixed, in order to establish a standard, where none existed before, prior to the delivery of the first machines. At the same time, head construction had to evolve into a semi-production process, rather then hand crafting them one at a time. A electronic video processing amplifier had to be designed and developed that would be capable of providing blanking and sync pulses, from the reproduced signal, that would be sufficiently free of noise to allow the replicated video signal to be handled, without difficulty, by conventional stabilizing amplifiers and clamps, located anywhere along the path of transmission. The reproduced tape picture had to be greatly improved over that shown in April, with respect to noise, overshoots and ringing, and horizontal stability. The entire machine, and all of the individual chassis, had to be repackaged and tested before delivery. The mechanical design details were endless. The top machine plate components (heads, pinch roller and capstan assemblies, reel tables, etc.) had to not only be reliable, but completely interchangeable. And always, there was the struggle for greater bandwidth and better signal-to-noise ratio. More hero medals, in October and November, went to John King, Roger Hibbard, and Tony Severdia, who, several times, started a work day at 8:00 in the morning and finished it 30 hours later. The Ampex Mark IV Video Tape Recorder went on the air, for the first time on November 30, 1956, from CBS Television City, in Hollywood, California, broadcasting a West Coast delayed broadcast of DOUGLAS EDWARDS AND THE NEWS. This, as far as it is known, was the first time in history that any video tape had been broadcast anywhere. NBC followed suit at the beginning of 1957, and ABC began delayed broadcasts from video tape, for the West Coast, at the beginning of daylight savings time in April of 1957. From that humble beginning, videotape recording has grown into a billion dollar industry that somehow touches our lives, in some way, every day. None of this could have happened without the participation of many others:

[HOME]......[EXTINCT DOCUMENTATION] Last updated: January 09, 2005 |