(International Video Corporation)

(International Video Corporation) IVC's

world headquarters building used to be at: 675 Almanor Avenue Sunnyvale,

California. International Video Corporation flourished from about 1967

well into the late 1980s. IVC manufactured dozens of models of VTR's, cameras,

film chains, switchers and other video equipment for the low end broadcast

and high end industrial markets. They sold equipment into virtually every

country in the world. I personally remember seeing the IVC color cameras

at TV station KRCR, channel 7 in Redding,

California, during a high school class field trip. (Click

on the small pictures to enlarge them. Use your browser's back button to

return.) . IVC's

world headquarters building used to be at: 675 Almanor Avenue Sunnyvale,

California. International Video Corporation flourished from about 1967

well into the late 1980s. IVC manufactured dozens of models of VTR's, cameras,

film chains, switchers and other video equipment for the low end broadcast

and high end industrial markets. They sold equipment into virtually every

country in the world. I personally remember seeing the IVC color cameras

at TV station KRCR, channel 7 in Redding,

California, during a high school class field trip. (Click

on the small pictures to enlarge them. Use your browser's back button to

return.) .

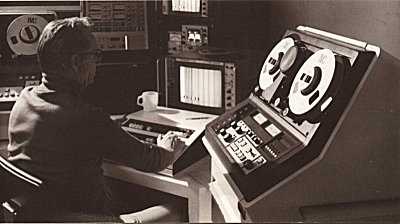

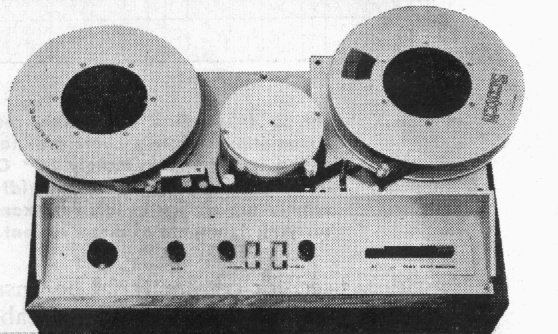

IVC 1-11: The broadcast VTR that never was!  The

IVC 1-11, 1 inch Broadcast VTR is designed for the user looking for the

performance of 1" VTRs without excessive cost and complexity. (Approximately

$36,000) Compact, flexible and simple to operate, the IVC 1-11 employed

a new signal system derived from the IVC-9000 mastering VTR, Dolby (TM)

Video processing and a dedicated integral digital timebase corrector. The

result is full bandwidth low noise video for a multigeneration performance

comparable with any broadcast VTR. The IVC 1-11 is available, with a variety

of packaging options including space saving transport and electronics assemblies

separable by up to 10 feet (3 meters). The

IVC 1-11, 1 inch Broadcast VTR is designed for the user looking for the

performance of 1" VTRs without excessive cost and complexity. (Approximately

$36,000) Compact, flexible and simple to operate, the IVC 1-11 employed

a new signal system derived from the IVC-9000 mastering VTR, Dolby (TM)

Video processing and a dedicated integral digital timebase corrector. The

result is full bandwidth low noise video for a multigeneration performance

comparable with any broadcast VTR. The IVC 1-11 is available, with a variety

of packaging options including space saving transport and electronics assemblies

separable by up to 10 feet (3 meters).

Easily

integrated with auto editing systems, the IVC 1-11 provides high speed

tape shuttle for fast access to any recorded tape segment. All controls

for monitoring and optimization are on the front control panel with clear

meter and/or LED readouts. A microprocessor based timer with programmable

memory makes scene material location and retrieval fast and accurate. A

full range of connectors, audio on XLR, video on BNC, is easily accessible

on the 1-11's rear panel. Along with a remote foot switch brake release,

for use with any 1-11 configuration. Easily

integrated with auto editing systems, the IVC 1-11 provides high speed

tape shuttle for fast access to any recorded tape segment. All controls

for monitoring and optimization are on the front control panel with clear

meter and/or LED readouts. A microprocessor based timer with programmable

memory makes scene material location and retrieval fast and accurate. A

full range of connectors, audio on XLR, video on BNC, is easily accessible

on the 1-11's rear panel. Along with a remote foot switch brake release,

for use with any 1-11 configuration.

(Information edited from a proof copy of the sales

brochure dated: 4/80)

This machine, sadly, never went into production. Only two prototype machines were built. The IVC 1-11 is a classic case of a product being to late for its market place. By the time this machine was ready for production, in 1980, the 1 inch C broadcast format had been adopted by the television industry. This truly was the last video recorder developed by IVC. I'd like to thank William Meyer for all of the excellent IVC historical information that he has provided for us here. IVC VCR-100:  IVC

VCR-100, Video Cartridge Recorder. IVC

VCR-100, Video Cartridge Recorder.

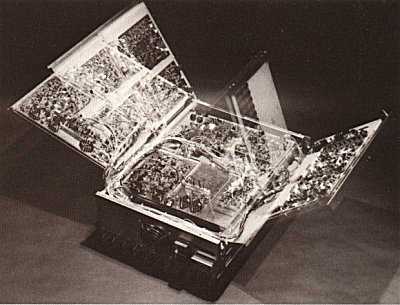

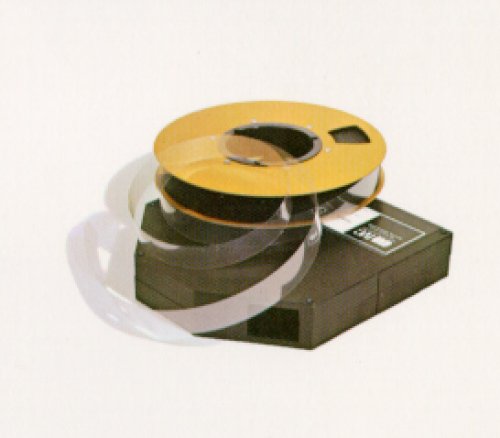

The VCR-100 was a video cartridge recorder and conformed to the same physical recording format as all of IVC's 1 inch reel to reel machines. A tape cartridge, unlike a cassette, does not contain an integral take up reel. Instead, the machine contains an internal, fixed take up reel. When a roll of tape weighs 6 to 8 pounds, the design engineer had to work over time to trim away the fat. Removing the take up reel from the cassette housing, and saving a pound or two, was totally logical. (More about this in a moment.) The 8" reel prior to installation in the cartridge.

The VCR-100 New Scotch 461 tape came with clear leader tape for use in this machine. The leader functioned as a component of the machine's auto threading system. The leader was removed when the tape was used on an open reel machine.  Loading

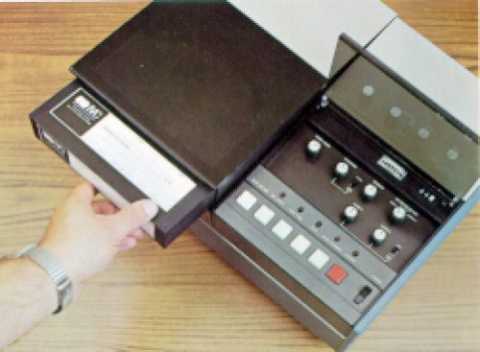

the cartridge into the IVC 100. Loading

the cartridge into the IVC 100.

At startup, the feed reel, inside the cartridge, would spin very quickly. In fact, it would spin so fast that it would literally launch the leader tape from the spool. The leader was then guided, by the walls inside the cartridge, to a special guide track called the "C channel". The C channel guided the leader tape around the intended tape path and delivered it to the internal take up spool, which was also spinning. The stiff plastic leader tape would remain in the C channel, but the much more flexible recording tape, would be pulled out of the C channel to drop neatly onto the guides and heads. This ingenious process, like most ingenious processes, works great. (...on paper!) . The VCR-100 had it's head drum mounted upside down. This allowed gravity to assist in the threading of the tape. This tid-bit of info was provided by William Meyer, who used to work at IVC. . If this sounds a bit like a Rube Goldberg mechanism to you, you're right! Panasonic's Omnivision format and CBS's EVR both worked this way, too. All of these formats had fixed internal take up spools. If anything went wrong and the tape or film jammed, you could not remove the cartridge! It required disassembling the machine, and attempting to rethread the tape onto the guides. Failing that, you spent the next hour or two pulling the tape out by hand and wrapping back it onto the feed reel! . IVC 500 Series VTR's:  IVC-500,

1 inch, reel to reel, colour VTR. IVC-500,

1 inch, reel to reel, colour VTR.

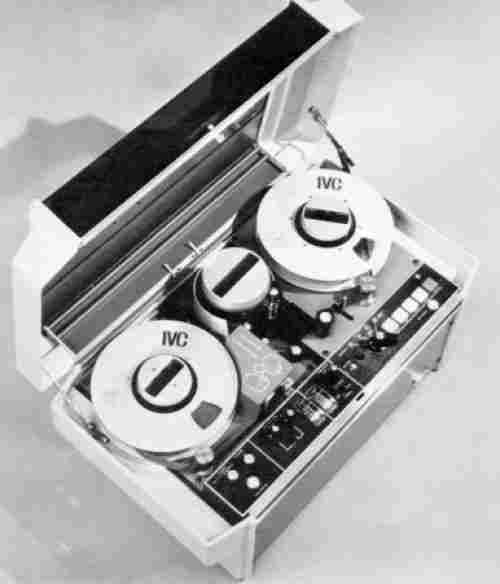

IVC 700 Series VTR's:  IVC-700,

1 inch, reel to reel, colour VTR. IVC-700,

1 inch, reel to reel, colour VTR.

New! IVC-711, close up look at this 1 inch, reel to reel, colour VTR.

New!  IVC-711,

a better view. IVC-711,

a better view.

More info and pictures

are needed!!! Help?

IVC-800 Series VTR's:

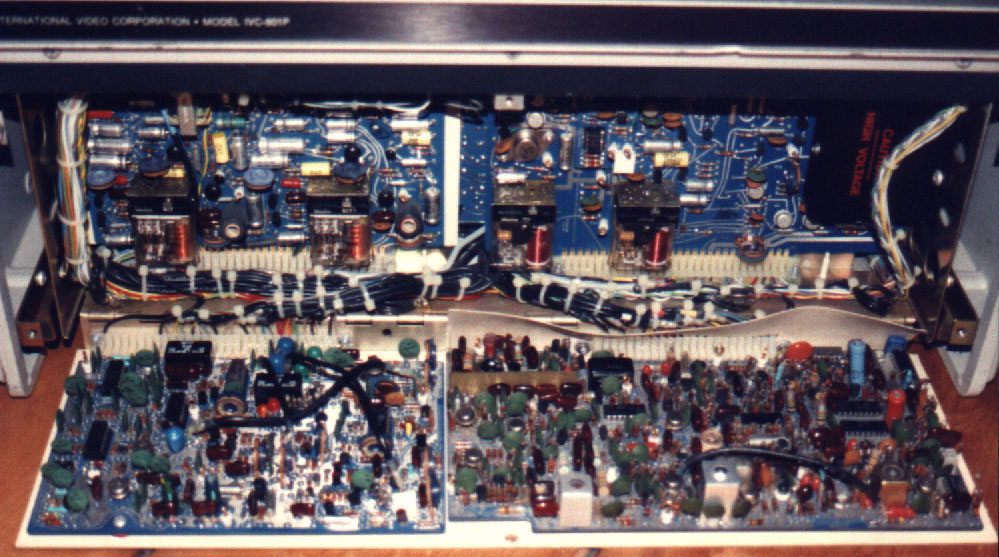

IVC-961P: 1.  2.

2. 3.

3. 4.

4. Note

2. Note

2.

For more info about this machine, Click here to visit John Sangster's IVC-961P page. IVC Time base correctors:  TBC-2001

TBC-2001

TBC-2002

TBC-2002

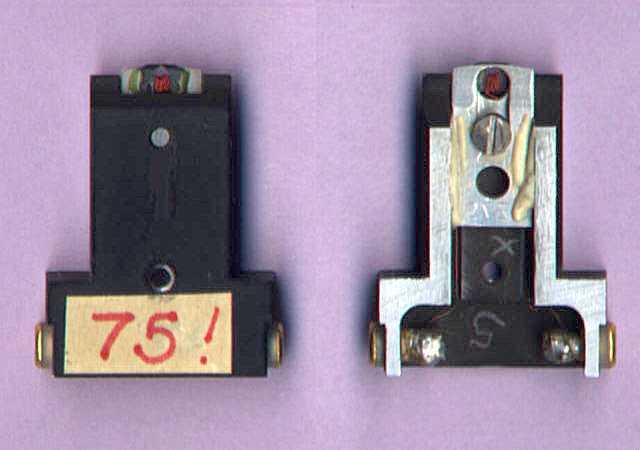

IVC Video Heads:  This is an example of the video head used in the model(s) 700, 800 and

900s. If you look very closely, you can easily see the ferrite (black)

material that formed the actual recording surface. The 7 or 8 turns of

microscopic copper wire, which transform the ferrite into an electromagnet,

are also visible in the picture. This fragile assembly is glued to an aluminum

mount which is called the "boot".

This is an example of the video head used in the model(s) 700, 800 and

900s. If you look very closely, you can easily see the ferrite (black)

material that formed the actual recording surface. The 7 or 8 turns of

microscopic copper wire, which transform the ferrite into an electromagnet,

are also visible in the picture. This fragile assembly is glued to an aluminum

mount which is called the "boot".

IVC-9000:  IVC-9000

- 2 inch Helical, Colour Editing VTR. Notes

3. & 5 IVC-9000

- 2 inch Helical, Colour Editing VTR. Notes

3. & 5

This machine was phenomenal! It worked in ALL world video standards. It had a whopping 8 Mhz direct (raw) bandwidth! The IVC-9000 used 2 inch video tape in a Segmented Helical Scan configuration. Video was direct recorded to tape. Specifications: Tape Width: 2 inch, Linear tape speed: 8.00 IPS, Scanner Speed: 9000 RPM, Relative tape speed: 1,500 IPS. Design Team:

The IVC-9000 had one other interesting mode. It could record a 655 line picture at 24 frames per second. This is specifically for the film industry. The model number of this film frame rate machine was: IVC-9000M, the M standing for MOVIE or maybe "costs even MORE". . Does anyone have any more information about the IVC-9000, especially the 24 FPS mode IVC-9000M? If so, please send me an email. Notes / Credits: 1. All material on this page (C)1998 Phydeaux SoftWorks / Richard Diehl. 2. VCR-100, IVC-700, IVC-871, IVC-961P & TBC's photos and information courtesy of John Sangster. 3. All IVC 1-11 photos and information provided by William Meyer. 4. Photo of the IVC-9000 provided by Wesley Orr. 5. Photo of the IVC-860 provided by Gary Duck. 6. Photo of the IVC-711 & IVC-801 provided by Michael Niermann. [HOME]......[EXTINCT DOCUMENTATION] Last updated: January 09, 2005 |