LabGuy's World:

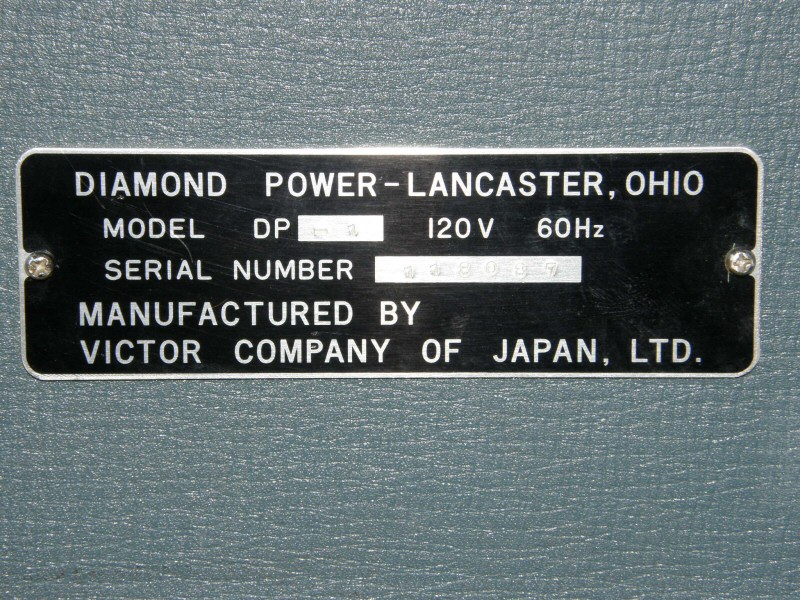

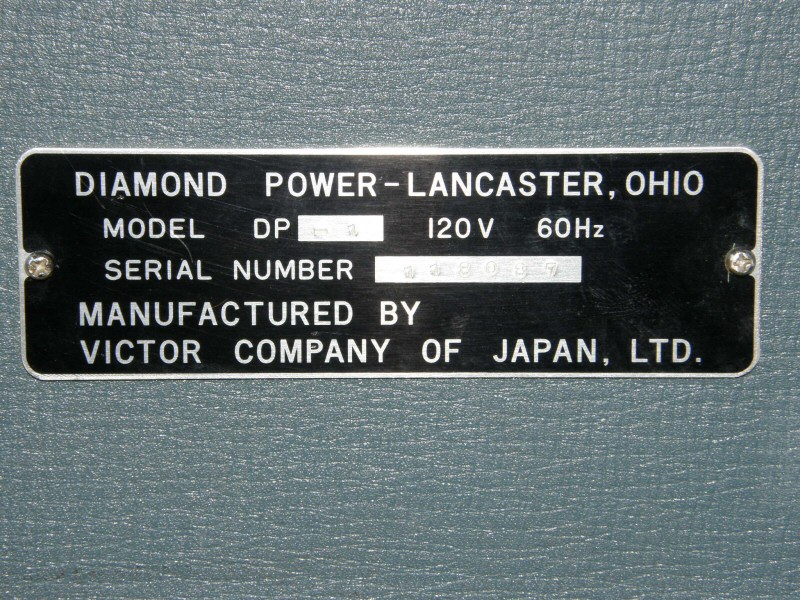

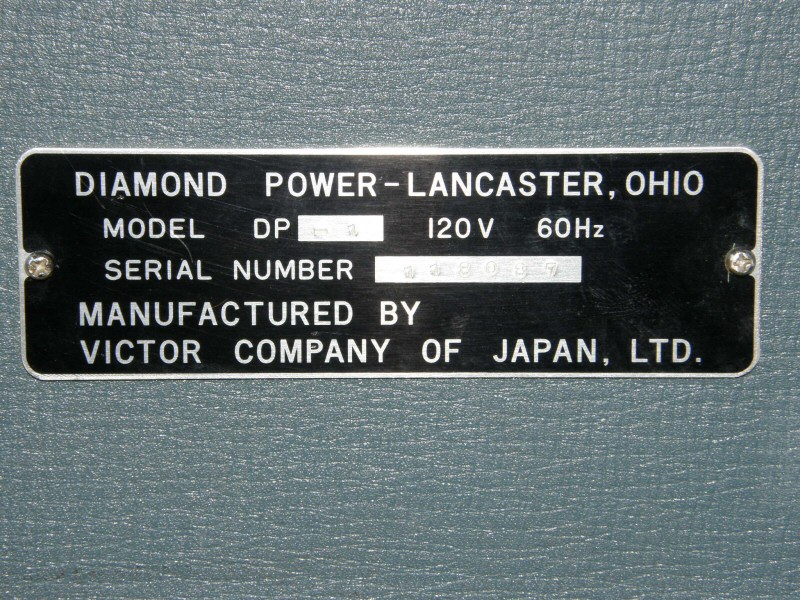

1968 Diamond Power DP-1 pre-EIAJ B/W VTR

New Addition! 080308

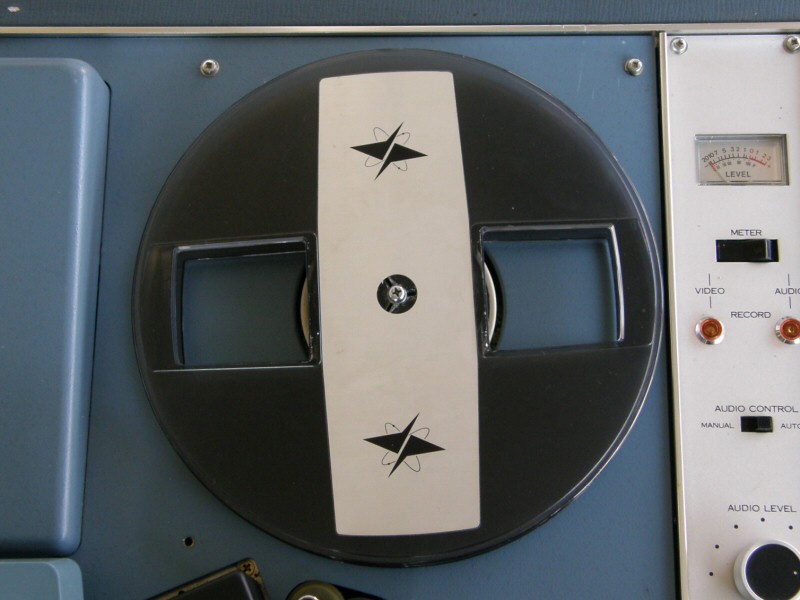

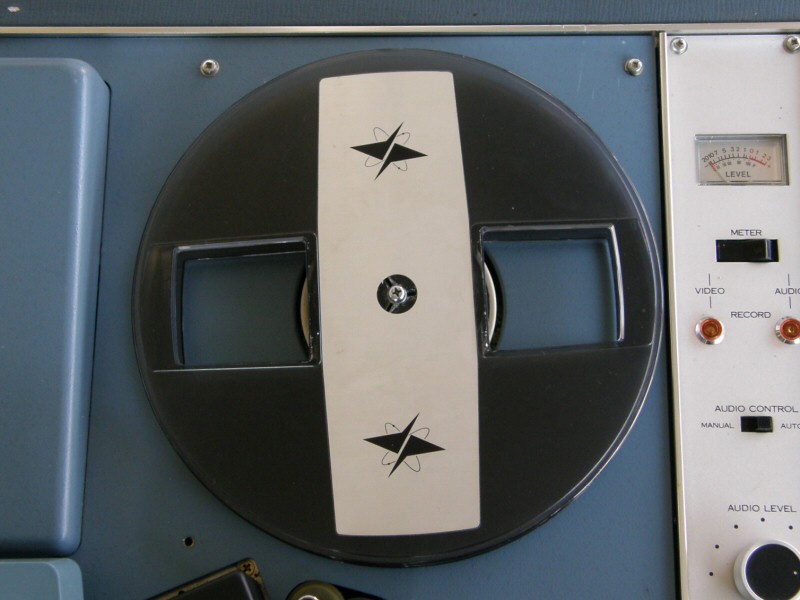

1968: Diamond Power DP-1 pre-EIAJ VTR

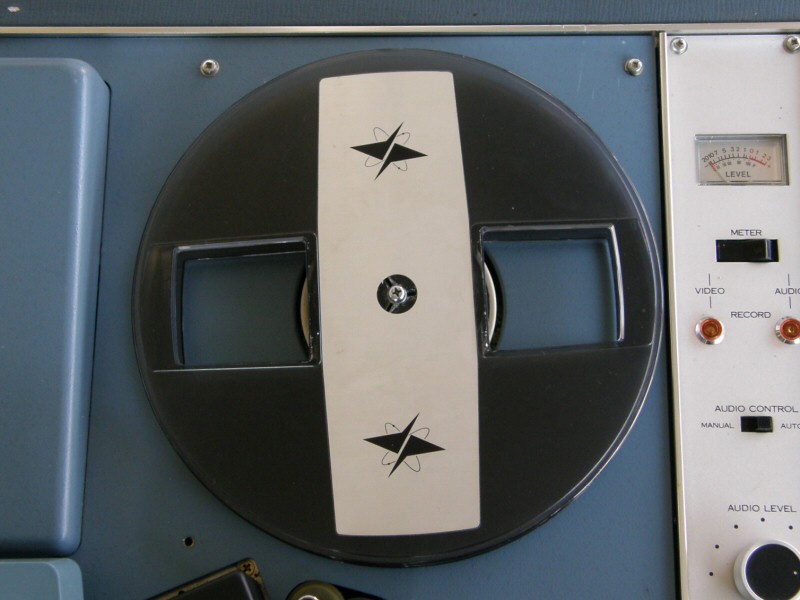

Dig the supersonic atomic logo! Model year approximately 1968. The Diamond Power DP-1 was actually manufactured by JVC for Diamond

Power. The DP-1 is a repackaged [Craig 6401] VTR. JVC,

like a lot of the Japanese manufacturers in the 1960s, marketed their products in the

United States under many names. JVC, Nivico and Craig are all JVC brand names. I know of

one other case of a rebranded JVC deck and that is the [JFD 700],

a rebadged [Craig 6407]. Does anyone know of any other

cross referenced JVC model numbers?

Diamond Power is a company that has been

in the industrial control and monitoring business since the 1950s or earlier. They

manufactured video equipment for monitoring blast furnaces and other super bright

industrial process, like welding, smelting and incinerating, using Farnsworth image

dissctor tube cameras. These processes are ideal for that type of camera as it is

famous for its lack of light sensitivity! The dissector lacked any form of charge

storage. It is an "instantaneous" imager. It's sensitivity is directly related to how

fast it is scanned. In the earliest days of television, Philo Farnsworth would actually

set entertainers on fire with the amount of light required to get a usable picture

from a dissctor tube. It's true! Look it up.

Diamond Power added this type of equipment to its product line up in the 1960s in order to stay current. So, they

Back to this video recorder. It features

a full field, slant track, two head frequency modulated recording system, an all

electronic rotary transformer head assembly, and can operate with 1/2" tape at 9-1/2

IPs for maximum 50 or 60 minute recording or playback time on either 7" or 8-1/4"

reels. The audio re-record capability makes it possible to re-record the sound track

without disturbing the video portion. Recordings made on the DP-1 should fully

interchange compatible with my [Craig 6402], which is on

temporary loan for a tape recovery job in Boston. The unit also has manual and

automatic audio and video level controls with built in metering, a built in 2:1 sync

generator, plus stop motion capabilities. The recorder measures 21" wide x 12" high x

18" deep and weighs 70 pounds.

8-1/4" reels? That explains why this deck

is so large! Several JVC innovations are immediatley apparent to my eye. The charcoal

grey metal alloy of the head drum is one. The slanted feed reel and absence of a tape

tension cotrol lever is another. Note the conspicuous absence of this "skew" control.

The rotary transformer in the head drum

is another clue that this early JVC technology. I could not show the transformer in

my DP-1 as the head drum cover is stuck fast. My rule of "do no damage" prevents me

from attempting to force it loose. I doubt the cover was removed since the deck was

assembled in 1968.

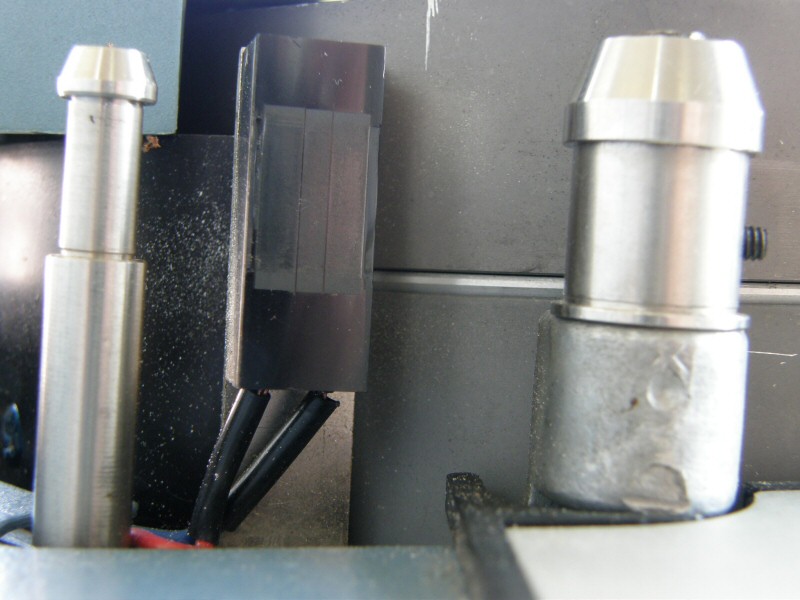

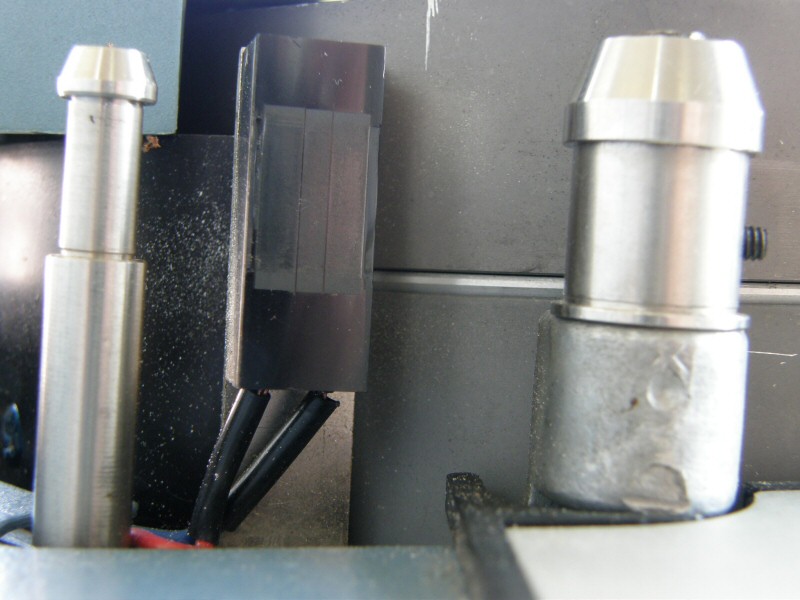

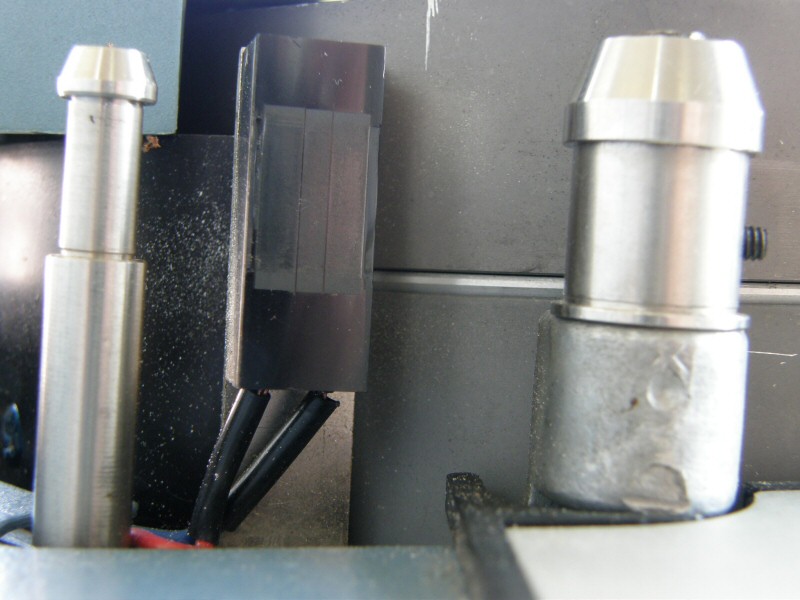

1968: Craig 6402 Scanner Innards

I include a photo of the head drum

innards of my Craig 6402 VTR, which is identical to the DP-1. The rotary transformer

is located at the center of the drum where the red and yellow wires are running out

to one of the video heads. The single PG, or Pulse Generator, coil is located at the

approximely 4 O'clock position on the drum also. This coil produces the pulse used

by the servo to lock head rotation to the vertical sync pulse of the video during

record OR to the control track pulse on playback. The capstan is not servoed, so the

heads must change phase to match the tape. In other recorders, the heads lock to a

crystal derived pulse and the tape speed is varied to bring the tracks under the

heads at the precisely correct time. Either method is valid. The latter being

employed in VTRs with editing capability.

The cause of the sticking head scanner

cover is now obvious in this photo. the foam rubber that was placed in there, most

likely for sound abatement, has turned to goop. Perhaps a blast of hot air from a

heat gun would break that loose? Why foam rubber under this cover? The scanner

probably sounds like a lawn mower when it is running. The heads impact the tape at

high speed, making a characteristic loud buzzing sound. The craig version of the deck

had a drop down, foam lined cover in an attempt to supress some of this buzz. All

helical scan VTRs make this sound and the bigger the drum the louder the buzz.

The scanner assembly, commonly called the

head drum, is approximately 5-11/16 inches in diameter. Working the math, I come up with

a circumference of 17.8678 inches. At 30 revolutions per second, this works out to 536

inches per second video head speed. Not disrepectable, the DP-1 should have a frequency

response in the range of 3 Mhz plus. The data sheet only gives this spec as a horizontal

resolution of 240 lines. That's right on if you go by the rule of thumb of 80 lines of

resolution per Mhz of frequency respoonse. Standard iron oxide can record approximetley

1000 magnetic reversals per inch. Taking the magnetic resolution of the tape surfaces

versus the desired frequency bandwidth is knwown as the time / space relationship in

magnetic recording.

In the photos at the top of this page, you

can't see the audio and control heads because they are covered in a black Faraday shield

resting between the drum exit guide and the capstan / pich roller. According to Paul Beck

of Emerson College, who is using my Craig 6402 at the moment, the placement of the sound

and control tracks is opposite of the other half inch formats. Normally, the audio is on

the top and the control track is on the bottom edges of the tape. In this format, they

are reversed with control track along the top edge and the audio on the bottom edge of

the tape. This has no impact at all on anything technical what so ever. It simply struck

me as an interesting point of trivia.

Read the product literature for the Diamond Power DP-1 VTR here:

[Product Flyer page 1]

[Product Flyer page 2]

WANTED: Service and or operators' manuals, power cord and tape reels for this machine.

|

[HOME]

[VIDEO RECORDERS MUSEUM]

Created: March 8, 2008 Last updated: March 8, 2008 |